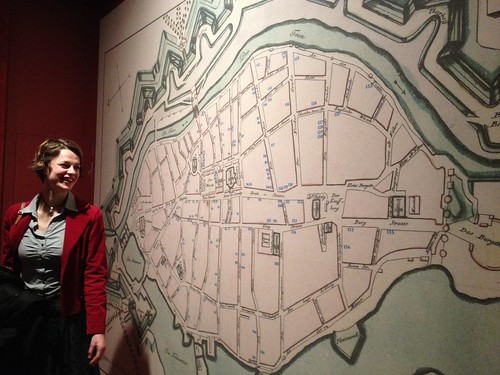

Making candy is a centuries old profession, easy to start yet difficult to master and develop a cult following. If you think the environment for candy is competitive today, hearken back to the early 1800s, when the medieval town of Lubeck, Germany was home to 135 marzipan “companies.” Back then companies were likely a small storefrontwith the basics found in an old fashioned candy store–a kettle, marble slabs, some molds.

I recently learned about the region’s delicious history–a place where the museum features figures carved in marzipan rather than wax–on a tour of mid-sized candy and chocolate factories with the German Sweets association. Since 1996, “Lübecker Marzipan,” from Lübeck in northern Germany, has been protected by an EU Council Directive as a “Protected Geographical Indication” (PGI) much like Champagne.

“That’s the marzipan I get at Cost Plus!” a friend exclaimed. Sold in 40 countries and on all continents, Niederegger‘s 500 dedicated* employees churn out about 30 tons of marzipan paste per day. If Lubeck could solve its debt problems with marzipan, everyone would be happy. Despite tough times the company’s sales have done quite well. Much like the “sin” products, they’ve found a little marzipan makes life rosier.

*One just retired after 45 years!

Our Factory Tour

It was an almond lover’s dream. After a steam blanching, winnowing to remove the skins, six women sit, pulling out any odd or unskinned almonds.

Overhead conveyors filled with almond paste dumped the mixtures into the vats. After roasting, the mixture cools in a 500-kilo capacity vat. Steaming dry ice does the job. We tasted chunks of freshly ground paste scooped out of the copper kettles, as well as the marzipan after roasting–which happens after the sugar is mixed with the almond paste. “Eat a lot,” our guide urged us.” We need to finish it all.” Sigh.

Through an extruder in which about 10 inch square logs of sugared almond paste squeeze through, chopped into 18 inch blocks, weighing about 15 kg, which are then wrapped to be aged in plastic cartons. There the flavor develops.

After aging, the special flavors such as a European rose water are added. Then it’s off to the enrobing lines where stamped out hearts take shape.

The seasonal-shaped marzipans are what’s really special. In December, Easter production begins. An army of standing bunnies emerged on a conveyor belt, destined to be torched–with a creme brulee style-and eyes added by bespectacled women holding tiny paint brushes. Dot. Dot.

Nearby, workers laboriously press molds with marzipan, just as in old times, for custom orders or as cake toppers. Consumers and businesses can order molds in any shape or saying, such as for corporate gifts. The company keeps the molds on hand for any future orders.

Some Business Best Practices

Niederegger handles export in-house to allow for quick decision making and personal relationships. They diversified with a series of German “nougat” products (which is similar to Italian gianduja), to reach non-marzipan loving candy lovers. The company does not private label and they would never entertain it due to their strong brand recognition and demand for their 300 products.

As with other factories we visited on this candy industry tour, employees at Niederegger are welcome to air any issues to management. Even broadcast news teams have visited the factory to see workers stretching and engaging in mini-workouts for ergonomic and overall health. Now a smoke-free company, it’s verboten to smoke during the workday. And production workers rotate roles for variety.

An SF Bay Area gal, you’ll find the world I blog about includes:

California food events and experiences, Artisan and gourmet food business,

and all things travel + ideas, both passions.